Golden Coal Series

Dry Coal Washery

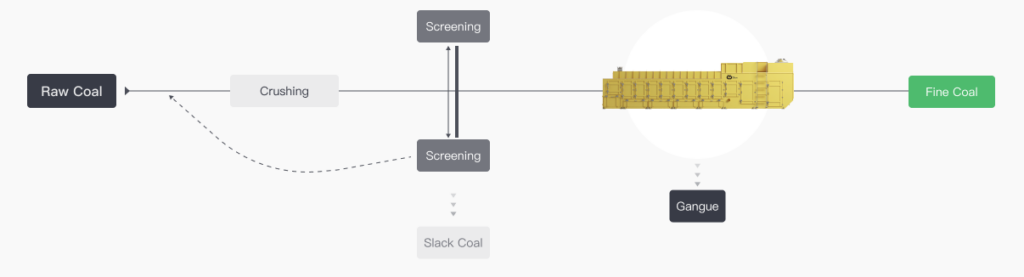

Replace hand sorting, jigging, shaking, and heavy medium processes, which can save on land, personnel, and capital costs for dry coal washery plants.

Economic Gains of 3.5 Million USD Annually with the Golden Coal Series Dry Coal Beneficiation

The Golden Coal Series is meticulously engineered for the precise separation of coal and gangue.

The HPY Finlay Dry Coal Sorting System employs X-ray dual-frequency detection technology, integrating a sophisticated artificial intelligence algorithm and high-speed air jets to efficiently segregate coal from gangue. Its modular structure design significantly diminishes the equipment’s footprint, making it 30% smaller than comparable alternatives, thereby simplifying maintenance. By expanding with additional modules, the processing capacity can reach 220t/h. Furthermore, the equipment features an explosion-proof design, rendering it suitable for operation in demanding environments.

The HPY Finlay Dry Coal Sorting System employs X-ray dual-frequency detection technology. This advanced technology integrates a sophisticated artificial intelligence algorithm and high-speed air jets to efficiently segregate coal from gangue. Furthermore, its modular structure design significantly diminishes the equipment’s footprint, making it 30% smaller than comparable alternatives, which greatly simplifies maintenance. Additionally, by expanding with additional modules, the processing capacity can reach 220t/h. Furthermore, the equipment features an explosion-proof design, rendering it suitable for operation in demanding environments

DRY COAL SORTING PROCESS: THE GOLDEN COAL SERIES DOES NOT USE WATER AND MAGNETITE, SO ENERGY CONSUMPTION IS LOWER THAN THE TRADITIONAL DRY COAL SORTING PROCESS.

Dry Coal Sorting System is purpose-built for the precise separation of coal and the thorough management of reject materials. It harnesses high-speed air jets, an advanced AI algorithm, and the choice of employing VIS HD imaging or single/dual-energy X-ray detection to achieve the accurate and efficient sorting of coal and reject materials.

With a specific focus on precise separation, the Dry Coal Sorting System is purpose-built for the thorough management of reject materials. In particular, it harnesses high-speed air jets, integrates an advanced AI algorithm, and offers the flexibility of employing VIS HD imaging or single/dual-energy X-ray detection. Consequently, these attributes combine to achieve the accurate and efficient sorting of coal and reject materials.

Efficient and Eco-Friendly Dry Coal Sorting System

Dry Coal Sorting System introduces a design that significantly minimizes the machine’s footprint, rendering it 20% smaller than comparable dry coal sorters with identical processing capabilities. The standard model efficiently processes up to 360t/h, with customizable options to meet specific customer demands by expanding the machine size. The Dry Coal Washery System introduces a design that significantly minimizes the machine’s footprint; consequently, it’s 20% smaller than comparable dry coal sorters with identical processing capabilities. Moreover, the standard model efficiently processes up to 360t/h.

The system is engineered with all key components designed to be explosion-proof, ensuring suitability for both surface and underground operational environments. The Dry Coal Sorting technology of the HPY Finlay Series is characterized by its waterless and chemical-free operation, with notably lower energy consumption compared to traditional coal washing and alternative coal sorting methods. It offers a clean, efficient, and environmentally responsible approach to dry coal sorting, replacing manual sorting, jigging, shaking, and heavy medium processes with exceptional accuracy. The HPY Finlay Dry Coal Sorting System proves cost-effective by reducing land, labor, and capital expenses for coal preparation plants.

Engineered with utmost care and attention to detail, the system incorporates all key components designed to be explosion-proof, ensuring its suitability for both surface and underground operational environments. Moreover, the Dry Coal Sorting technology of the HPY Finlay Series distinguishes itself with its waterless and chemical-free operation. This approach leads to notably lower energy consumption compared to traditional coal washing and alternative coal sorting methods. Consequently, it offers a clean, efficient, and environmentally responsible approach to dry coal sorting. By effectively replacing manual sorting, jigging, shaking, and heavy medium processes, it achieves exceptional accuracy. As a result, the HPY Finlay Dry Coal Sorting System proves highly cost-effective, effectively reducing land, labor, and capital expenses for coal preparation plants.

| Model | Weight(t) | Machine Power(kW) | Particle Size(mm) | Processing Capacity(t/h) | Machine Size(mm) (L×W×H) | |

|---|---|---|---|---|---|---|

| Camera | TC1200 | 12 | 16 | +50-300 | 100-140 | 12000*1800*2500 |

| TC1400 | 14 | 22 | +50-300 | 120-160 | 12000*2000*2500 | |

| TC1600 | 16 | 28 | +50-300 | 140-180 | 12000*2300*2500 | |

| TC1800 | 20 | 32 | +50-300 | 150-190 | 13500*2500*2800 | |

| TC2000 | 22 | 36 | +50-300 | 160-200 | 13500*2700*2800 | |

| TC2400 | 24 | 32 | +50-300 | 200-280 | 12000*3500*2500 | |

| TC2800 | 28 | 44 | +50-300 | 240-320 | 12000*3500*2500 | |

| TC3200 | 32 | 56 | +50-300 | 280-360 | 12000*3500*2500 | |

| Single/ Dual-energy X-ray | TX1200 | 12 | 16 | +50-300 | 100-140 | 12000*1800*2500 |

| TX1400 | 14 | 22 | +50-300 | 120-160 | 12000*2000*2500 | |

| TX1600 | 16 | 28 | +50-300 | 140-180 | 12000*2300*2500 | |

| TX1800 | 20 | 32 | +50-300 | 150-190 | 13500*2500*2800 | |

| TX2000 | 22 | 36 | +50-300 | 160-200 | 13500*2700*2800 | |

| TX2400 | 24 | 32 | +50-300 | 200-280 | 12000*3500*2500 | |

| TX2800 | 28 | 44 | +50-300 | 240-320 | 12000*3500*2500 | |

| TX3200 | 32 | 56 | +50-300 | 280-360 | 12000*3500*2500 | |