What is Dry Coal Beneficiation?

Enhancing Efficiency and Sustainability

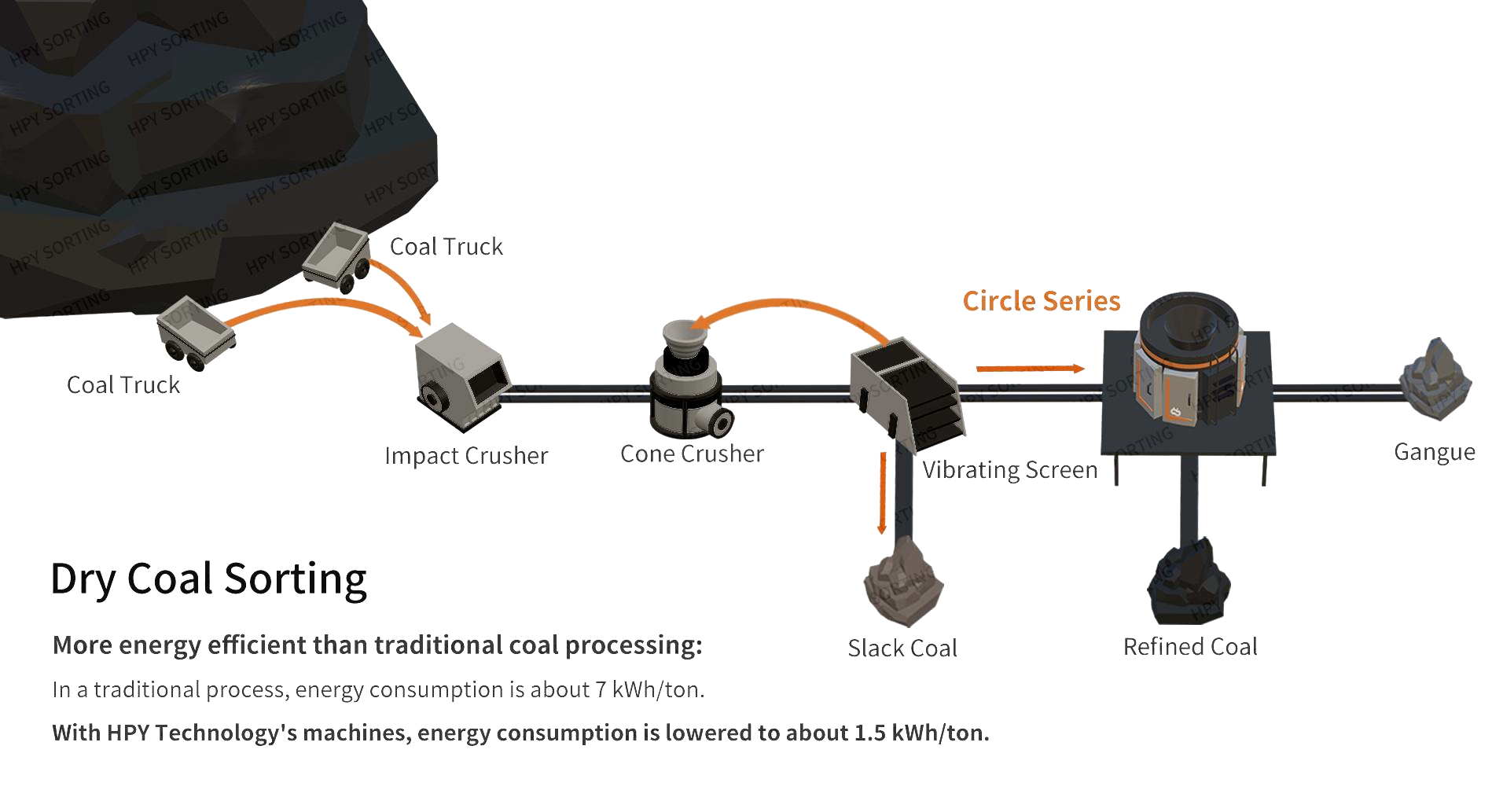

Dry Coal sorting is a highly effective physical method that harnesses external forces to separate coal from undesired reject materials through the use of Dry Coal Separation and Dry Coal Beneficiation Technology. It operates by meticulously testing and identifying each coal deposit based on its unique physical attributes. These attributes, including color, luster, density, reflection, and refraction, are meticulously analyzed by optical or electrical sensors to facilitate the precise segregation of coal from reject materials. Embracing coal sorting technology, including dry coal separation and dry coal beneficiation technology holds the potential for substantial cost savings and the optimization of mining operations.

The system operates by meticulously testing and identifying each coal deposit based on its unique physical attributes. Optical or electrical sensors are employed to analyze attributes such as color, luster, density, reflection, and refraction, aiding in the precise segregation of coal from reject materials. Embracing coal sorting technology offers substantial cost savings and optimizes mining operations

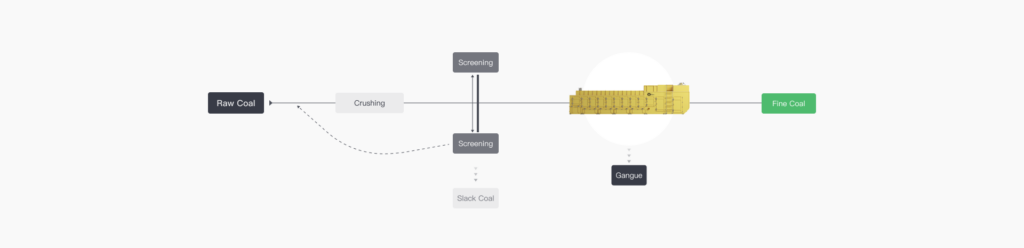

This coal sorting process encompasses three key steps:

Identification of Coal:

This initial stage involves pinpointing the coal deposits in the midst of heterogeneous mineral formations through Dry Coal Sorting.

Data Collection through Advanced Sensors:

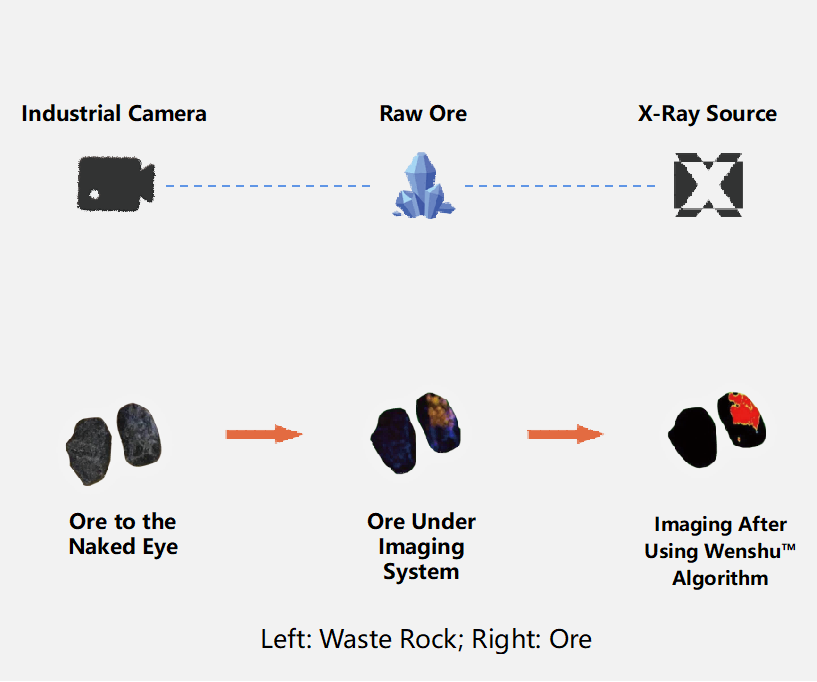

Cutting-edge sensor-based technologies have revolutionized the data collection process. These innovations leverage artificial intelligence, deep learning, machine vision, and image recognition to enhance data accuracy and efficiency.

Sorting:

Once data is collected, the sorting phase is initiated. It is during this stage that coal is meticulously separated from the reject materials.

Unlocking the Potential of AI & ML

While sensor-based coal sorting has been an integral part of the mining industry since the 1970s, recent technological advancements have significantly elevated its efficacy. Particularly, integrating XRT X-ray sorting technology with deep learning capabilities has transformed waste rock and previously deemed valueless stockpile materials into valuable industrial-grade coal with substantial potential for comprehensive utilization. These cutting-edge technologies have ushered in a new era of efficient and sustainable resource management, empowering mining operations to optimize their processes and enhance their environmental footprint.

Sensor-based coal sorting has been integral in mining since the 1970s. Recent advancements, especially the integration of XRT X-ray sorting with deep learning, have greatly improved its effectiveness. This innovative approach maximizes low-grade coal resources, turning waste rock and previously considered valueless stockpile materials into valuable industrial-grade coal. These technologies usher in an era of efficient and sustainable resource management, helping mining operations optimize processes and reduce their environmental impact. View Golden Coal Series & Circle Series to learn more.